BUNKER PRO 2.0 is a versatile tracked mobile chassis designed for a wide range of industrial and specialized applications. It features responsive and intuitive control, a large development space, and compatibility with various custom solutions across multiple industries. With its independent suspension system, heavy-duty shock absorption, strong climbing ability, and stair-climbing capability, it delivers excellent adaptability in challenging environments. BUNKER PRO 2.0 is ideal for the development of special-purpose robots in areas such as inspection and exploration, rescue and explosive ordnance disposal (EOD), specialized filming, and tactical transportation, providing a reliable and robust mobility platform for robotic solutions.

| Name | Quantity |

|---|---|

| BUNKER PRO 2.0robot body | 1 PCS |

| Battery charger (AC 220V) | 1 PCS |

| Aviation plug male(4Pin) | 1 PCS |

| USB to CAN communication module | 1 PCS |

| FS remote control (optional) | 1 PCS |

| Parameter Types | Items | Parameter |

|---|---|---|

| Mechanical specifications | ||

| L × W × H (mm) | 1080 x 785 x 470 | |

| Wheelbase (mm) | 575 | |

| Track Width(mm) | 150 | |

| Curb weight (kg) | 225 | |

| Battery Type | Lithium Iron Phosphate | |

| Battery parameters | 72V 50AH | |

| Power drive motor | 2x1800W brushless servo motors | |

| Steering | Track type differential steering | |

| Suspension Type | Christie Suspension & Matilda Four-Wheel Balanced Suspension | |

| Drive Motor Gear Ratio | 1:7.5 | |

| Drive Motor Sensor | 2500 PPR Optical Incremental Encoder | |

| Performance parameters | ||

| Maximum Loaded Speed (m/s) | 1.5 | |

| Minimum turning radius (mm) | Can turn in place | |

| Maximum Climbing Ability (Unloaded) (°) | 30° (Capable of stair climbing) | |

| Maximum obstacle crossing(mm) | 180 | |

| Maximum Ground clearance (mm) | 120 | |

| Rated Endurance Time (h) | 2.5 h (Fully loaded on concrete) | |

| 3.5 h (Unloaded on concrete) | ||

| Maximum distance (km) | 15KM (full loaded) | |

| 20KM (Unloaded) | ||

| Charging time (h) | 2.5 | |

| Working temperature (℃) | -20~60℃ | |

| Braking Distance | ||

| (Unloaded, friction coefficient 0.5) (m) | 0.7 | |

| IP Grade | IP67 | |

| Control | RC transmitter | 2.4G/extreme distance 200M |

| System interface | CAN | |

| Control mode | Remote control Control | |

| Command control mode |

FS RC transmitter is provided (optional) in the factory setting of BUNKER PRO 2, which allows users to control the chassis of robot to move and turn; CAN and RS232 interfaces on BUNKER PRO 2 can be used for user’s customization.

This section provides a brief introduction to the BUNKER PRO 2 mobile robot platform. It is convenient for users and developers to have a basic understanding of BUNKER PRO 2 chassis.

The rear electrical interface is shown in Figure below, with the components labeled as follows:

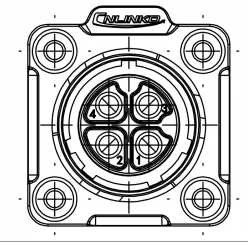

The definitions of Q1 communication and power interface as shown in Figure below